INVENTIONS

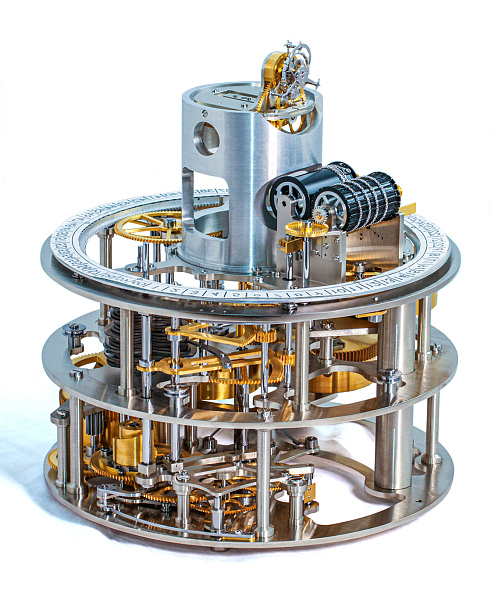

Having decided to test myself in the world of haute horlogerie, in 2003, I began with the creation of a table clock with tourbillon. Why did I start this? Because I had read in a watchmaking magazine that nobody had ever made tourbillons in Russia. I was hooked.

Konstantin Chaykin began his watchmaking career with a tourbillon, the globally-recognised symbol of haute horlogerie, thereby setting a high bar for his future manufactory.

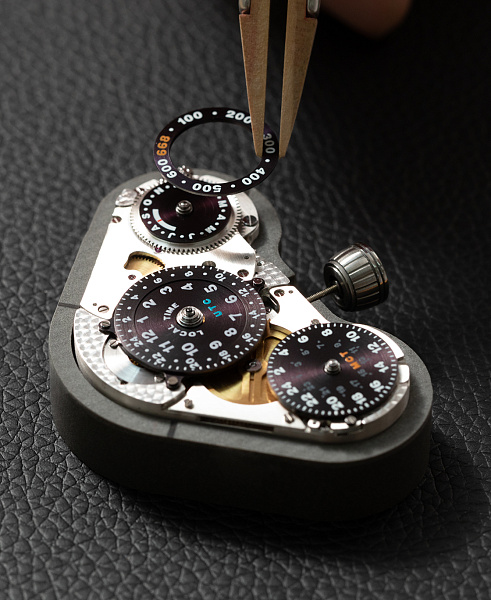

When Konstantin Chaykin mastered tourbillons, the haute horlogerie classic, he realised that he could reproduce any previously-invented watchmaking device. However, this didn’t appeal to him. He immediately understood that it would be much more interesting to invent things himself. Every watch by Konstantin Chaykin is equipped with complex mechanical calibres, which are made and based exclusively on his own movements, functions and designs. Therefore, a Konstantin Chaykin watch is incomparable in the global watchmaking industry. Moscow, 29th April. At the plenary session of the XIII International Forum “Intellectual Property – XXI Century”, held by the Chamber of Commerce and Industry of the Russian Federation, the ceremony awarding Russian inventor Konstantin Chaykin with the WIPO gold medal took place. The combination of extraordinary creative thinking and the refusal to follow the beaten path is typical of the inventive style of Konstantin Chaykin, characteristics shared with many of his watches.

On October 13, 2022, 9th Temporis International Awards ceremony was held in Zurich. Konstantin Chaykin participated in the ceremony and joined the Temporis Hall of Fame. The award was established by Dan Vardie, publisher of Temporis watch media. He stood behind the establishment of the Temporis International Awards Jury that selects the winners each year among participating watchmakers. In addition to the award, Dan Vardie created a tradition of an "honour ceremony" for the most outstanding and famous masters of Haute Horlogerie in the world - introduction to the Temporis Hall of Fame. There are currently 27 outstanding people in the Hall, including legendary watchmakers and inventors like Kurt Klaus, Philippe Dufour, Kari Voutilainen, Richard Mille, Michel Parmigiani and Ludwig Oechslin. For the first time in the history of watchmaking, Russian watchmaker Konstantin Chaykin was privileged to join the Temporis Hall of Fame in 2022.

On November 17, 2022, Konstantin Chaykin was awarded the "Distinguished Inventor of Russian Federation" title – the official certificate, recognizing the master's long and successful career as an inventor was signed by the president Vladimir Putin. Many scientists, engineers, experimenters who have contributed significantly to the development of both Russian and global science, were given this award. And now Konstantin Chaykin officially joins them.

The Medal of the Russian Ministry of Finance "For Diligence and Art" was given as an award at the ceremony which was held on 27th of December, 2022. It has a long history: it was presented by the Ministry of Finance of the Russian Empire at all national exhibitions in the XIXth and early XXth centuries. In 2022, the traditional award was returned by the Russian Ministry of Finance. The winners are the leading representatives of the jewellery and watchmaking industries, including the famous Russian watchmaker and inventor Konstantin Chaykin.

Konstantin Chaykin – author of 96 patents for his inventions as well as 62 utility model patents (as of Febrary 2024), the most of any watchmaker in the world. In total he has designed over 30 mechanical calibres and functional models.

Inventions of Konstantin

Chaykin